Tell us about your company!

– Saft is a wholly owned subsidiary of TotalEnergies, a broad energy company that produces and markets energies on a global scale: oil and biofuels, natural gas and green gases, renewables, and electricity. Saft has been around for over 100 years, and in that time our longer-lasting batteries and systems have provided critical safety applications, back-up power and propulsion for our customers across a broad range of industries. Our innovative, safe, and reliable technology delivers high performance on land, at sea, in the air, and in space.

What challenges do your products solve for the customer?

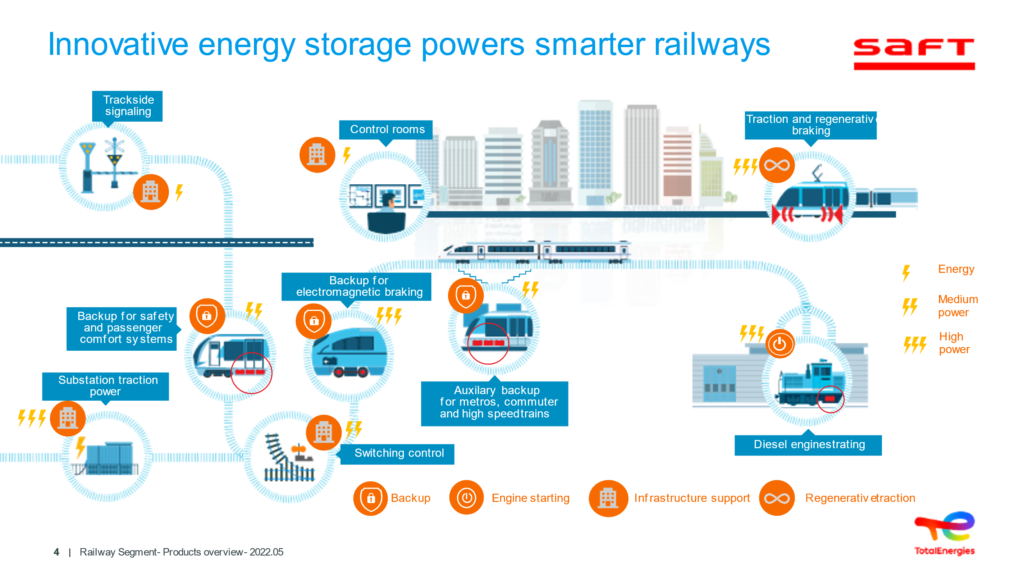

– Saft provides innovative energy storage powers for smarter railways from trackside signaling to the control room. We make sure our customers have back-up power, we help with engine starting, infrastructure support and regenerative traction. Back-up power means that critical functions like air-conditioning and door opening are assured in case of a power failure.

What important trends do you see in the development of the railway industry?

What important trends do you see in the development of the railway industry?

– The decarbonization of the rail transportation industry is highly connected to our core business; our batteries last three times longer than lead-acid batteries, making them the sustainable choice. We are seeing the roll out of hydrogen fuel cells and batteries for traction applications in multiple unit trains. Even hydrogen trains need batteries! In addition, the use of battery technology in trains and trams will bridge catenary / primary power gaps in the route. And hybrid traction solutions can be used to avoid the use of diesel in depots and dense population centers.

Why is it an advantage to work with companies from Sweden in a global market?

– For security, we do what we promise, and because sustainability is important to us. We notice that sustainability is also becoming more and more important to our customers. In Sweden, in order to manufacture batteries, you must recycle batteries to obtain a license, and not just our own batteries, everyone’s. Therefore, we were early with setting up our own battery recycling facility in Oskarshamn where we will recycle 300 tons of cadmium in 2023.

We were early with setting up our own battery recycling facility in Oskarshamn where we will recycle 300 tons of cadmium in 2023.

– Sweden has an optimal climate for batteries. Our batteries are robust, weather- and wind-resistant and not as sensitive to extreme temperatures as those made using different electrochemistries. We have gathered the experience from our various areas of operation and take that knowledge with us in every project. For instance, in Halshuk at the northwestern point of the island Gotland outside Sweden, the lighthouse has a battery that is 54 years old and still works. In Fairbanks, Alaska, we have a battery the size of a football field. That battery should be able to supply all of Fairbanks with power for 15 minutes. Temperatures in Fairbanks can drop to -50°C, so if there is a power cut, the wires freeze. The battery replaces a diesel unit that used to always be on as a backup, and now they have a 15-minute set-up time instead.

Translated to trains, this means that our batteries can do a lot, from illuminating the emergency lighting, to automatic opening of doors so that warm (or cold) air is not unnecessarily released when all doors open.

Why are you a member of Swerig?

– We are members of Swerig to expand our network and for opportunities to meet key people and customers. In addition, Swerig helps us to get the most out of participating in Swedish and international fairs. For possibilities!