Tell us about Isoflex!

Isoflex factory in Gustafs, Sweden.

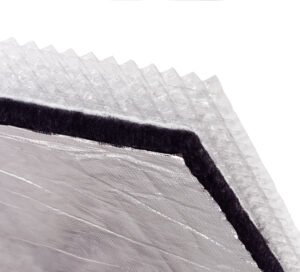

– Isoflex, founded in 1949, specializes in Moniflex, an environmentally friendly insulation system primarily used in trains, trams and metros. Today, Moniflex is integrated into most high-speed trains worldwide due to its unique properties. The material serves two primary purposes: it acts as a thermal barrier, preserving hot or cold air, and it functions as a condensation barrier, preventing moisture infiltration. Additionally, it has acoustic properties, effectively reducing noise levels. Isoflex provides comprehensive guidance to clients on how to optimize their insulation needs, offering more than just a product. Using a sandwich-like approach, we tailor each project to meet the client’s specific requirements by combining the material with other elements to achieve the desired outcome. Isoflex is privately owned and employs approximately 16 people, mainly in production, with its headquarters in Gustafs, Sweden. Globally, we have established a network of agents and distributors, and we believe in quality and long-term relationships.

What challenges do your products solve for the customer?

– One of the key functions is that Isoflex’s insulation system, Moniflex, is very lightweight. You don’t want to transport extra weight on trains, but rather prioritize passengers and cargo. The material has low density and retains its weight as it doesn’t absorb water but rather drains moisture from walls and ceilings. This means that heating and air conditioning can be downsized since there’s no need to cool or heat away excess moisture.

– Furthermore, Moniflex is an environmentally friendly solution, primarily based on cellulose. This also means that it is easy to handle during installation, whisch is another appealing feature. Isoflex holds certifications according to Reach, ISO 9001, and ISO 14001, and it meets fire and smoke safety requirements.

What important trends do you see in the development of the railway industry?

– I have a positive outlook for the future in the railway industry. There is significant investment in railway infrastructure and rolling stock, which is essential for reducing carbon emissions. Environmental sustainability is becoming increasingly important, even in the manufacturing of trains, where the Moniflex material offers a distinct advantage. Historically, many manufacturers optimized insulation for space considerations without focusing on the material itself. However, today, there is a greater emphasis on the product, weight reduction, and sustainability, resulting in increased competition. While operating in a large world market, we’re a relatively small player, and need to expand our presence.

Moniflex is made from the same, natural raw material as paper – cellulose.

Why is it an advantage to work with companies from Sweden in a global market?

– I have worked in exports for over 30 years in various companies, and Swedish products, in general, have a good reputation worldwide. They are considered innovative, of high quality, and dependable in terms of delivery. As individuals, we find it easy to build relationships. Essentially, Sweden is a country with which people are eager to do business.

Why are you member’s of Swerig?

– We want to stay updated on industry trends and have a better understanding of the global market, which can be challenging as a smaller player. By learning about trends and statistical reports from various parts of the world, we gain valuable insights into the market. We have previously participated in a joint booth at InnoTrans, an experience I highly recommend. The exchange of ideas during meetings is invaluable.